This article was first published in March 2020, the month many facilities shut down in reaction to the first wave of the pandemic. Most stayed closed, or partially closed, for much of the following two years.

As a result, previously postponed preventative maintenance, and unnoted reactive issues that arose while partially shuttered can impact your organization’s overall productive capacity upon reopening. In March 2022, the scarcity of skilled tradespeople is making it difficult for some FMs to get their maintenance items resolved quickly.

Review the best ways to operate effectively with Flagship's new Healthy Workplace Guide to Staying Open Responsibly.

The first step to having a strong maintenance program that can easily be followed is understanding the difference between reactive, preventive, and predictive maintenance.

What is reactive maintenance?

Fixing a piece of equipment because it’s broken seems like a simple and intuitive reaction. That is why reactive maintenance tends to be a highly common form of maintenance, for individuals and businesses. Reactive maintenance occurs once a machine is not operating up to normal standards and addresses maintenance problems as they arise.

Example: The department printer is displaying an error and is no longer printing or copying. The error cannot be cleared by users. A professional will need to be called to fix the printer.

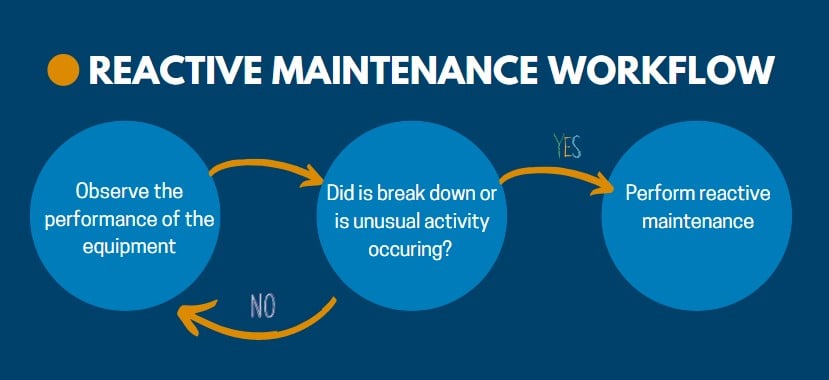

The workflow usually looks like this:

With reactive maintenance, the costs only occur if there is an issue with the machine. Therefore, when you implement a reactive maintenance program, it should be in areas that incur less initial costs and require lower staffing needs.

For reactive maintenance situations, the sudden costs of time down, professional service, and parts should be easily handled by the organization.

In the printer example:

- If there are other printers within the facility that users can access, having one printer down may not have much of an adverse effect on production.

- However, if the printer is a main source of production and needs to be running at optimal capacity at all times, the cost of it going down can be detrimental to the business.

This is why it is very important to determine the different types of maintenance needs throughout your facility.

What is preventive maintenance?

Preventive maintenance is a more proactive form of maintenance. It is performed at regular intervals and generally based on the manufacturer’s parameters and determined by length of time or amount of usage. It is also referred to as planned maintenance.

Preventive maintenance involves performing maintenance tasks even though the equipment is currently operating to normal standards. Performing preventive maintenance helps you avoid unexpected breakdowns and the costs that would be associated with the machine’s downtime and lack of production.

A good example of preventive maintenance can be shown with maintaining a car.

The car manufacturer provides parameters based on the number of miles driven or a certain length of time. For instance, oil changes should occur every three months or 5,000 miles, whichever happens first. If you follow the preventive maintenance directions for your vehicle, it is consistently maintained, and it decreases the fear of breakdowns due to oil use.

The goal of preventive maintenance is to extend the life of assets, only lose production during scheduled maintenance times, improve the overall efficiency of the machine, and reduce overall maintenance costs.

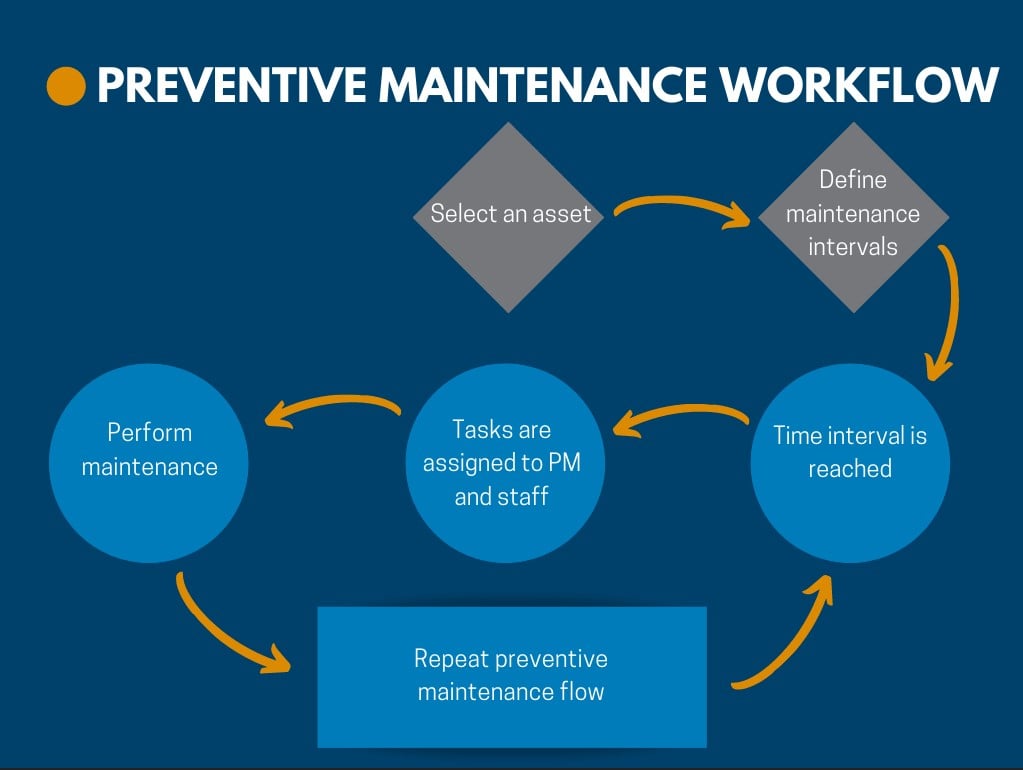

A typical workflow would look like this:

In the right situations, preventive maintenance can be more cost-effective than reactive maintenance strategies. When applied, it can provide an overall savings of approximately 15% during the machine’s lifetime. However, it can also be more difficult to justify taking the machine offline and stopping production when the machine is working efficiently.

One flaw of preventive maintenance is that maintenance is based on the theoretical rate of failure rather than the actual equipment performance. Since the failure rate is predominantly hypothesized by the manufacturer, it may be much more conservative than the actual rate of operational loss, unlike predictive maintenance.

What is predictive maintenance?

Predictive maintenance can happen when you take into account more detailed information about how your equipment is actually used. Today, it is possible for more operations to perform predictive maintenance due to advances in technology that allow you to connect your asset to your CMMS and collect your data on a continuous basis.

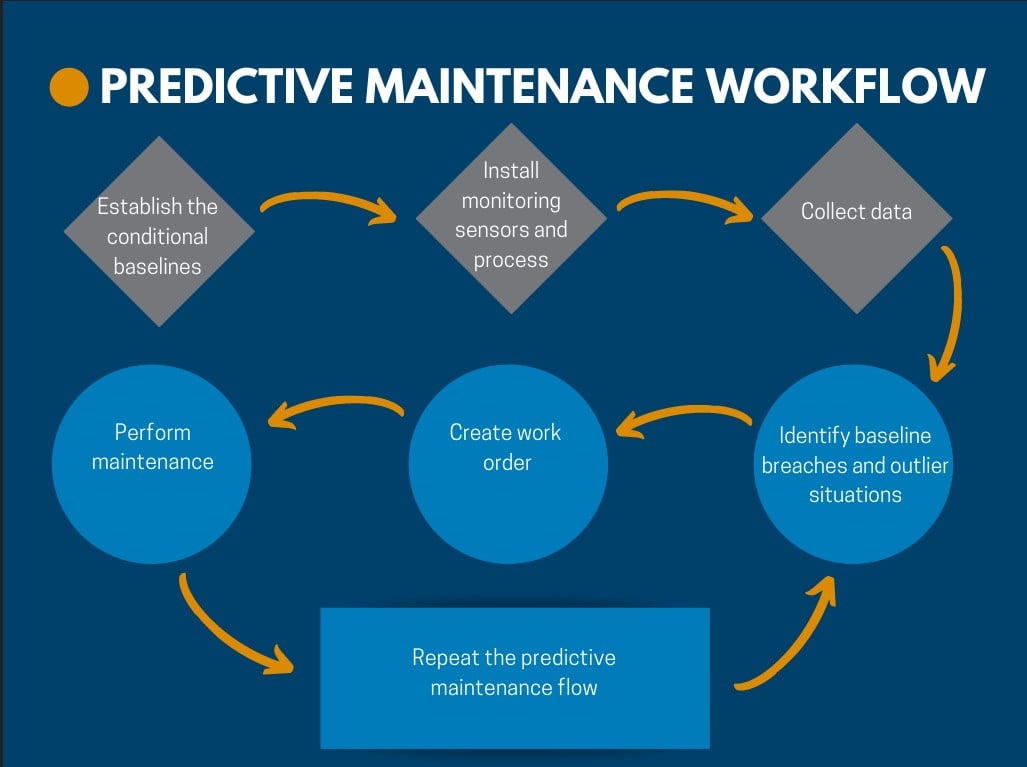

The predictive workflow would look like this:

Predictive maintenance is based on experience and is performed based on historical and current data. It's a process that directly monitors the asset’s performance during normal operation and establishes maintenance criteria based on predicted failures.

Preventive maintenance, a good example can be used with owning and maintaining a car.

As in the previous example, oil changes, based on the manufacturer’s suggested maintenance can easily be implemented. However, what if you drive an average of 100 highway miles each day?

According to the preventive guidelines, you’ll need an oil change every 50 days. However, if you log your miles, check your oil, and develop a system that concludes when your specific car needs oil based on your circumstances, you may find that you need an oil change every 80 days versus every 50. That will reduce your number of oil changes from 7.3 preventive changes to 4.5 predictive changes each year. In this example, it can reduce your annual need by almost half.

With predictive maintenance, the data collected helps put systems in place so that you don’t run a part until it fails, and you don’t replace a part when it still is running strong. It allows you to establish protocols that help optimize your operational strategies by conducting maintenance only when completely necessary. However, it is a complex system that takes a lot of setup time, access to technology, consistent data management, and the adoption of all users.

The good news is that the extra effort can pay off. Its application can help your organization save 25% to 30% in annual maintenance costs when done correctly.

Predictive maintenance is a healthy balance between reactive and preventive maintenance. By connecting technologies, maintenance teams can effectively plan to implement the right asset with the right part and the right person at the right time.

Flagship's customizable approach to your facility's needs will help you protect employees and your assets now and into the future.

Email a facilities expert today and get the help you need to balance your maintenance plans.

Leave a Comment