Winter weather may look different every year, but one thing remains constant: facilities need to be prepared for sudden temperature drops, storm activity, and seasonal wear on critical systems. Even when long-range forecasts suggest a milder season for parts of the country, regions like the Pacific Northwest, the northern Rockies, the Great Lakes, and areas of Alaska are still likely to experience colder conditions, increased moisture, and periods of heavy snowfall.

For facility leaders, “mild” doesn’t always mean low-risk. Aging infrastructure, fluctuating temperatures, staffing constraints, and unpredictable weather patterns can all increase the burden on HVAC systems, roofs, walkways, and essential equipment. Winterizing your facility remains one of the most effective ways to protect your operations, control costs, and strengthen year-round resilience.

Below are several proactive steps your team can take to keep your facility safe, efficient, and winter-ready.

Inspect Your Roof & Physical Structure

Your facility’s roof and exterior structure are your first line of defense against winter weather. A proactive inspection now can prevent costly leaks, energy loss, and emergency repairs once temperatures drop.

Start With a Thorough Roof Assessment

If your building has a flat, accessible roof and your team is trained to perform inspections safely, begin by walking the perimeter and working inward. Remove any debris or standing water, and check for:

- Soft or weakened areas

- Loose or damaged flashing

- Gaps, tears, or warping in the roofing membrane

- Signs of water intrusion or pooling

These early indicators are often easy to miss but can lead to serious structural or interior damage if left unaddressed.

For pitched roofs, it’s best to partner with a qualified professional who can safely inspect the incline and evaluate shingle integrity. They should also confirm that all gutters and downspouts are clear and directing water away from the building, a critical step in preventing ice dams and winter drainage issues.

Evaluate Windows, Doors, and Seals

Once your roof is cleared, move to your building envelope. Inspect windows and doors for:

- Cracking or gapping caulk

- Separation from the frame or surrounding structure

- Noticeable drafts or moisture around the casing

These issues can cause significant heat loss, drive up energy costs, and create uncomfortable indoor environments. A quick reseal or repair can make a measurable difference in winter performance.

Check Surrounding Areas and Exterior Conditions

While you’re examining the facility’s exterior, address any vines, mold, or vegetation growing up the structure. These can accelerate deterioration and mask underlying issues.

This is also an ideal time to confirm that all locks, access points, and security systems are operating properly, especially as the darker, colder months can increase the risk of break-ins and after-hours access.

Test Your HVAC & Lighting Systems

As temperatures drop, your HVAC and lighting systems become critical to maintaining safety, comfort, and operational continuity. Because these systems work harder during winter months, now is the ideal time to verify that everything is functioning efficiently and reliably.

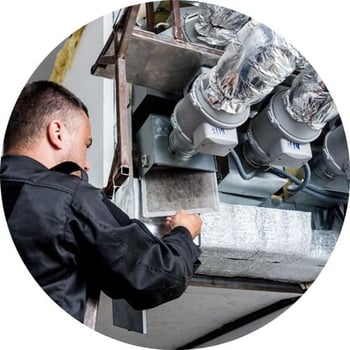

Perform a Comprehensive HVAC Inspection

Heating systems that have been idle or lightly used throughout the year may struggle when demand suddenly increases. Ramping up the heat too quickly, or doing so without routine maintenance, can lead to breakdowns, reduced air quality, and unexpected downtime.

Before cold weather arrives:

- Replace or clean air filters

- Inspect belts, coils, and electrical components

- Verify thermostat and control settings

- Ensure dampers and actuators are working correctly

- Check for airflow imbalances or inconsistent temperatures

These steps help reduce energy waste and prevent early-season failures, which are far more costly and disruptive during peak winter operations.

Confirm Lighting System Reliability

Lighting systems also face winter challenges, especially in regions with shorter daylight hours or extreme cold. Inspect all fixtures, emergency lighting, sensors, and exterior illumination to ensure:

- Adequate brightness for safety

- Functional occupancy sensors and timers

- Proper performance in low temperatures

- No damaged wiring, water intrusion, or flickering

Well-functioning lighting supports worker safety, improves visibility in snow and heavy rain, and helps maintain secure access points.

Ensure Proper Ventilation in Life Sciences Facilities

For life sciences environments, such as diagnostic laboratories, vivariums, and animal care facilities, ventilation is critical. These spaces require precise control of airflow, temperature, and humidity to maintain compliance and protect research integrity.

Verifying that your HVAC system can maintain stable environmental conditions throughout winter helps safeguard:

- Sensitive experiments

- Specimen and equipment integrity

- Regulatory compliance

- Overall employee and animal well-being

Build In Redundancy

Even with a strong preventive and predictive maintenance program, unexpected failures can still occur, especially during winter. Heavy storms, freezing temperatures, and prolonged outages all increase the strain on your facility’s infrastructure. That’s why redundancy is a critical part of an effective winter preparedness strategy.

Prepare for Power Interruptions and Outages

Winter storms can damage utility lines and disrupt service for hours or even days. To maintain operations and protect occupants, every facility should have a reliable backup system in place. This may include:

- A secondary power source, such as a generator or battery storage system

- Clearly defined emergency procedures for safely transitioning to backup power

- Regular testing to ensure your redundancy systems activate as intended

Backup power doesn’t just keep the lights on; it protects equipment, maintains indoor temperatures, and reduces the risk of costly downtime.

Maintain Access Control During Emergencies

If your access control system relies solely on your primary electrical feed, a power outage could lock out employees, vendors, or emergency responders. Ensure your system includes:

- A backup power supply or battery unit

- Regular battery checks and replacements

- Clear instructions for manual override if needed

Maintaining access during outages is essential for business continuity, safety, and security.

Prepare for Freezing Risks and Pipe Bursts

Temperatures below freezing significantly increase the likelihood of frozen lines and pipe ruptures. A burst pipe can cause thousands of dollars in damage within minutes. To reduce risks:

- Insulate exposed or vulnerable piping

- Maintain consistent indoor temperatures, even in low-traffic areas

- Know the exact location of your main shutoff valves

- Ensure staff can quickly access and shut off water if a rupture occurs

- Rapid response is the single most effective way to limit damage when a pipe bursts.

Winter may bring uncertainty, but preparation doesn’t have to. With thoughtful inspections, reliable backup systems, and a proactive maintenance strategy, you can safeguard your facility against the most common cold-weather risks. Now is the time to close gaps, reinforce your systems, and get ahead of potential issues before temperatures drop. If you’re looking for support, from seasonal maintenance to emergency response, Flagship’s facilities experts are here to help strengthen your operational resilience and keep your buildings winter-ready.

If you’re looking for support, from seasonal maintenance to emergency response, Flagship’s facilities experts are here to help strengthen your operational resilience and keep your buildings winter-ready.

Protect your people, safeguard your assets, and stay ahead of winter weather.

Leave a Comment